The business model for photovoltaic (PV) frames might appear straightforward—procure raw materials like aluminum rods and ingots, process them into frames, and earn from processing fees.

However, in this low-barrier industry with dispersed market concentration, how can companies differentiate themselves and build a sustainable competitive edge?

🚀 The Power of Custom Aluminum Ingots

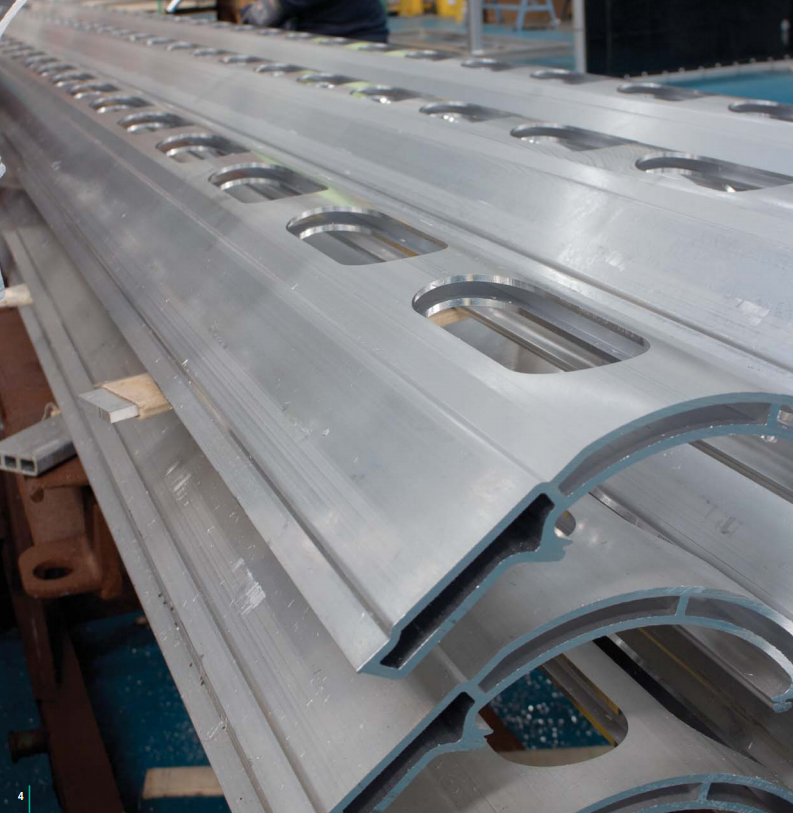

Custom aluminum ingots are key to optimizing PV frame performance. Tailored specifically for solar applications, these ingots undergo extrusion to create the lightweight, corrosion-resistant frames that hold solar panels in place.

Given the challenging outdoor environments where solar panels operate, material selection becomes critical.

⚙️ Key Alloys Driving Solar Innovation:

– 6063-T5 & 6063-T6: Excellent surface finish with good strength, suitable for standard applications.

– 6005-T6: Preferred for high-strength frames due to better structural integrity, fatigue resistance, and superior anodizing quality.

This blend of alloys ensures the frames are lightweight yet durable, capable of withstanding environmental stressors such as wind, rain, and UV exposure—ultimately reducing installation complexities while maintaining longevity.

🚀 The Power of Custom Aluminum Ingots

Building a moat in this segment means more than just processing aluminum. It involves precise alloy selection, cutting-edge machining, and sustainable practices, ensuring products that balance strength, durability, and recyclability. Companies leveraging this expertise can offer better performance and reliability, securing long-term customer trust in a competitive market.

The road to success in PV frame manufacturing isn’t just about materials—it’s about transforming those materials into high-performance, sustainable solutions. 🌱

Now we have various range of aluminum ingots for your options:

Diameter: 90/100/110/120/127/150/152/178/203/228/254/320

#SolarEnergy #PhotovoltaicFrames #AluminumIndustry #Sustainability #Innovation #Manufacturing #AluminumIngotSupplier