LED strip lights deliver flexible, energy-efficient lighting for homes, commercial spaces, and architectural projects. However, achieving professional-grade results requires pairing them with precision-engineered aluminum channels—critical for heat dissipation, mechanical protection, and optical control. With countless manufacturers competing globally, how do you identify the right partner? This guide breaks down key selection criteria using technical benchmarks and end-user application insights.

Why Aluminum Channels Are Non-Negotiable for LED Strips

1. Thermal Management Extends LED Lifespan

Aluminum’s thermal conductivity (160–180 W/m·K) draws heat away from LEDs, reducing junction temperatures by 15–20°C compared to exposed installations8. This prevents premature lumen depreciation and extends operational life by 30%.

2. Application-Specific Optical Performance

-

Cabinet Lighting: 10mm Slim profiles (e.g., Modern Aluminum 1010B) mount discreetly under shelves, delivering glare-free task lighting for kitchens or displays.

-

Cove & Wall Washing: Recessed channels with 60°–90° reflectors create seamless indirect lighting, eliminating “dotting” and scalloping effects.

-

Architectural Outlines: IP67-rated inground profiles (e.g., Modern Aluminum Facade Series) embed into walls or curbs, enabling weather-resistant accent lighting.

3. Durability Meets Aesthetics

Anodized aluminum (≥10μm thickness) resists corrosion in high-humidity zones5. Polycarbonate diffusers (opal/clear) reduce glare by 70% while achieving >90% light transmission

5 Critical Manufacturer Selection Criteria

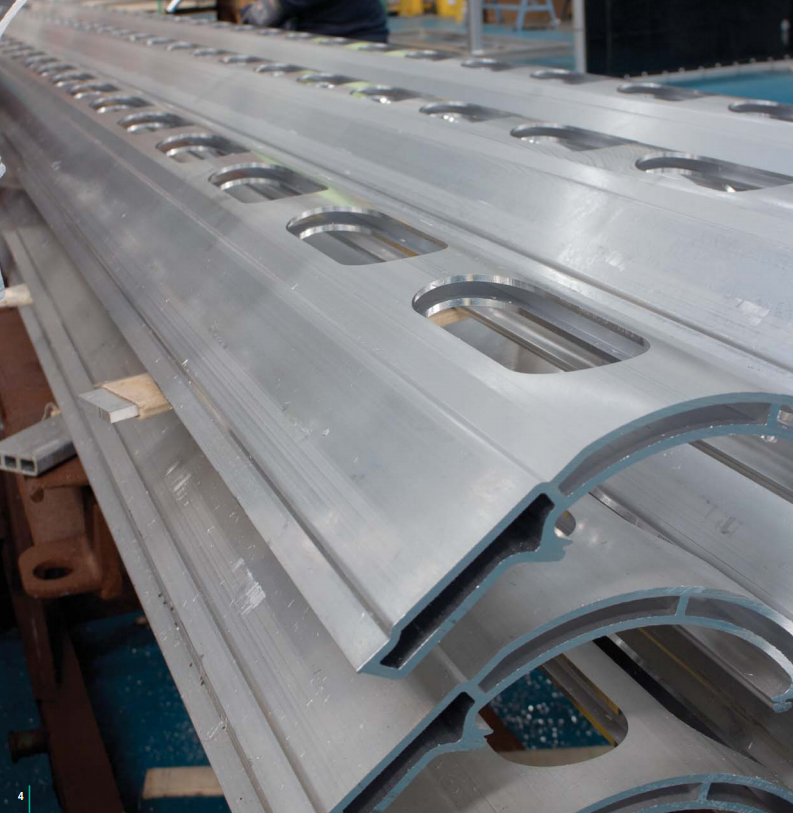

1. Material & Process Standards

-

Alloy Grade: 6063-T5 aluminum ensures hardness and extrusion stability (SGS test repost reference).

-

Dimensional Tolerance: ±0.1mm prevents misalignment with diffusers/end caps.

-

Surface Treatment: Anodized/powder-coated finishes withstand salt spray (500+ hours).

2. Product Range Depth

Leading manufacturers offer channels for all major applications

| Profile Type | Key Variants | Installation Context | Industry Terminology |

| Surface Mount | Wing Type | Ceilings, retail displays, cabinets, wardrobe | “Adhesive/Screw Fix” |

| Recessed | Slim Trimless | Drywall, ceilings, cabinets, wardrobe | “Plaster-in Mud-in” |

| Corner | 90° Triangular | Stairs, alcoves | “Dual-Output Asymmetric” |

| Specialized | Flexible/Bendable | Columns, curves | “Radius-Compliant” |

3. Aluminum Profile Validation

Request test reports with metrics like:

SGS Chemical Composition Test Report:

SGS Physical Property Test Report:

4. Diffuser Customization

Material: Polycarbonate (impact-resistant) vs. silicone (flexible).

Optics: Prismatic for sparkle, frosted for uniform glow, clear for RGB effects.

5. Certification & Compliance

IP Ratings: IP54 (indoor) to IP68 (pool/parking submersion)

Choosing a manufacturer with rigorous extrusion tolerances, thermal validation, and global certifications ensures your LED projects meet performance, safety, and aesthetic goals. Request samples to verify finish consistency and mechanical fit before volume commitments.