Cutting Through Complexity: Die Design Realities for EV Aluminum Extrusions

Having spent years in aluminum extrusion sales, I’ve seen firsthand how the push for lighter, stronger frames in Electric Vehicles (EVs) strains conventional die design. These profiles aren’t just complex – they demand precision engineering to avoid costly failures.

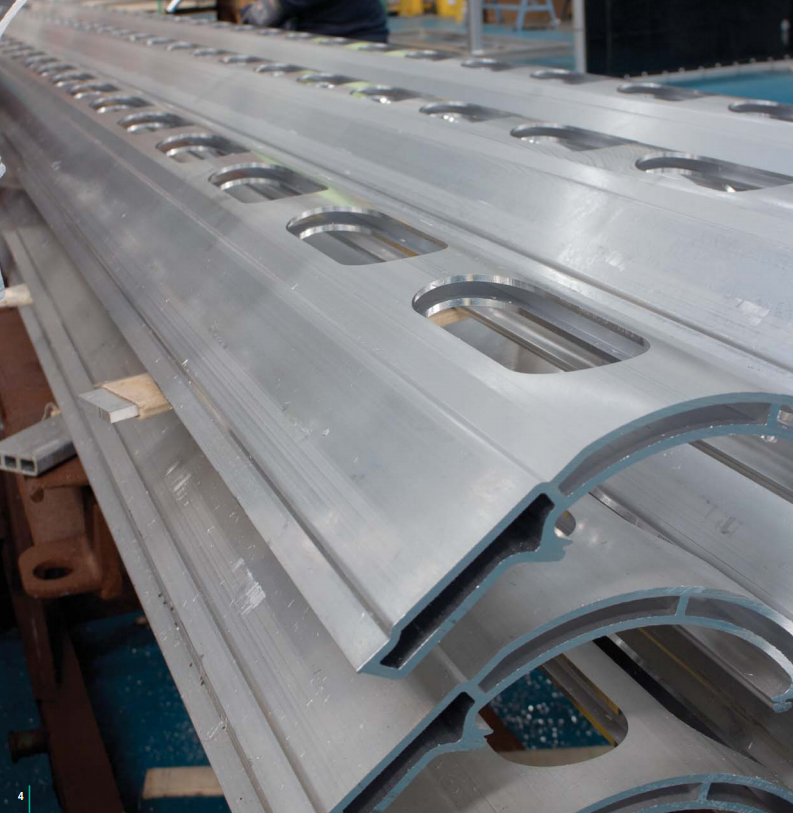

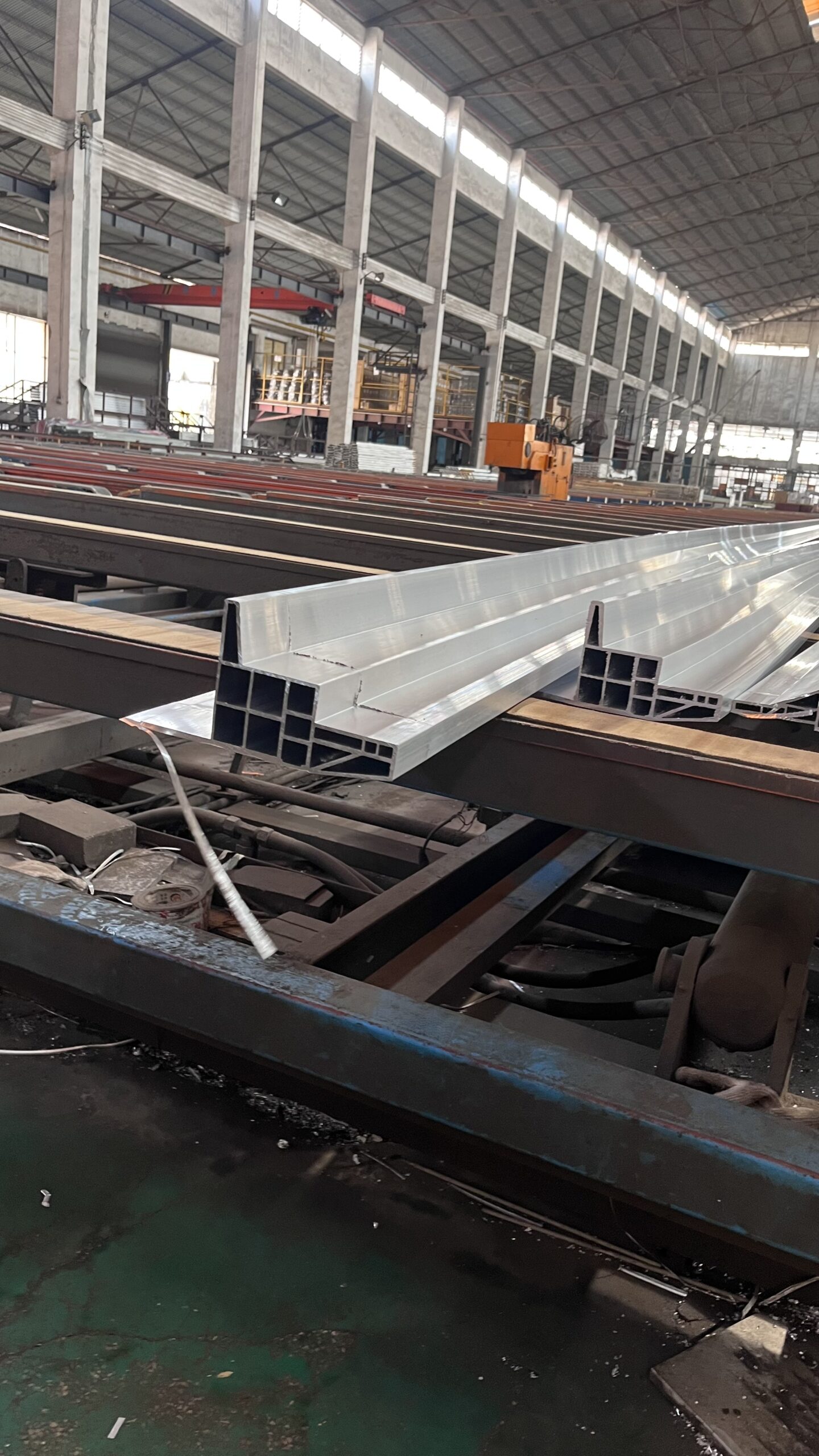

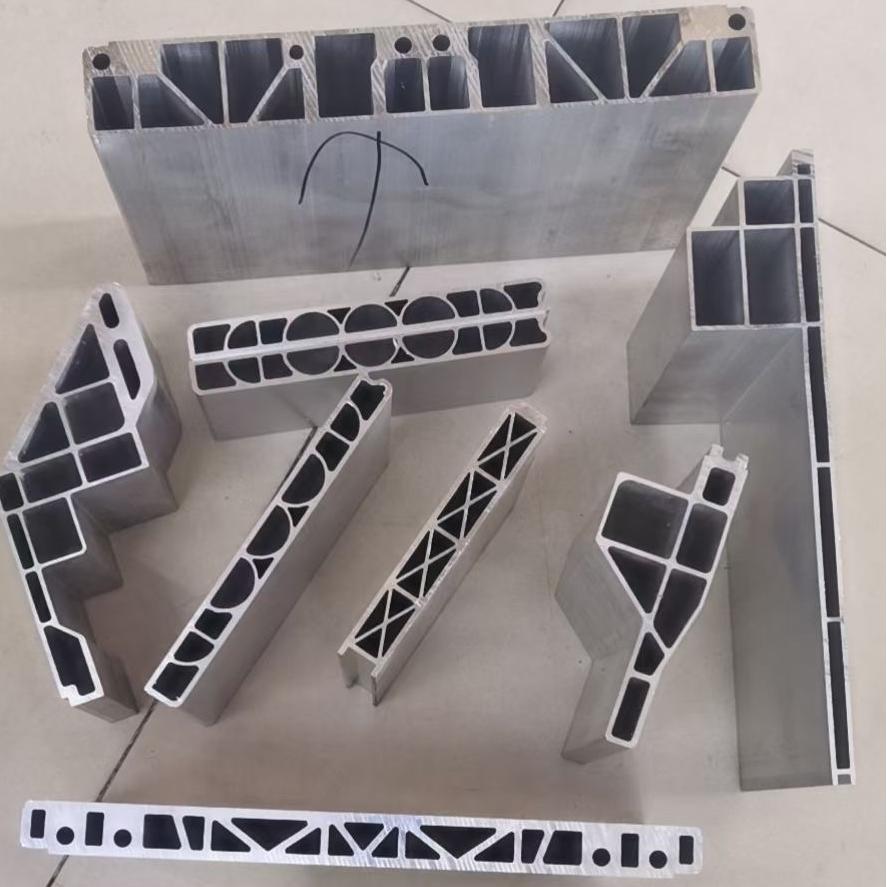

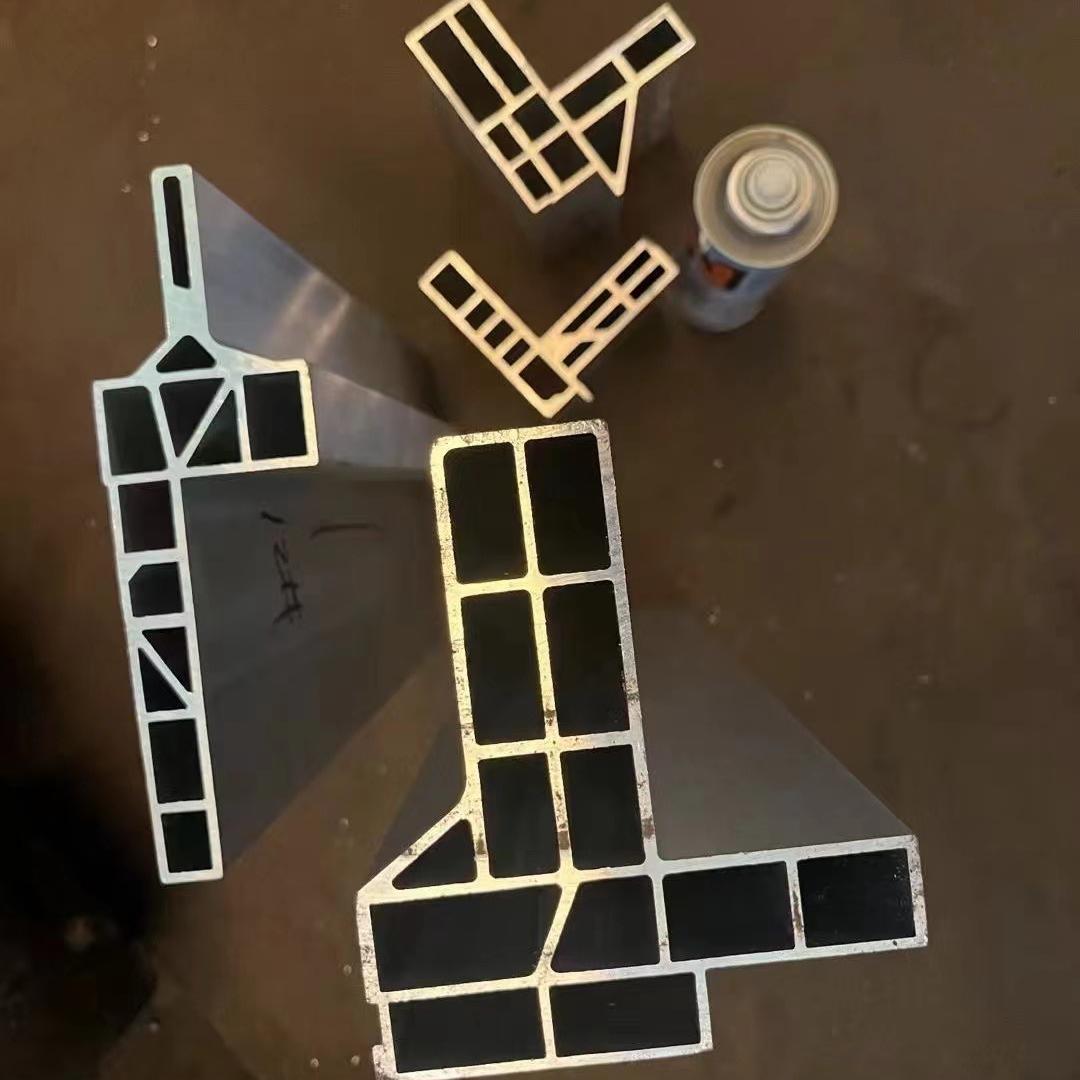

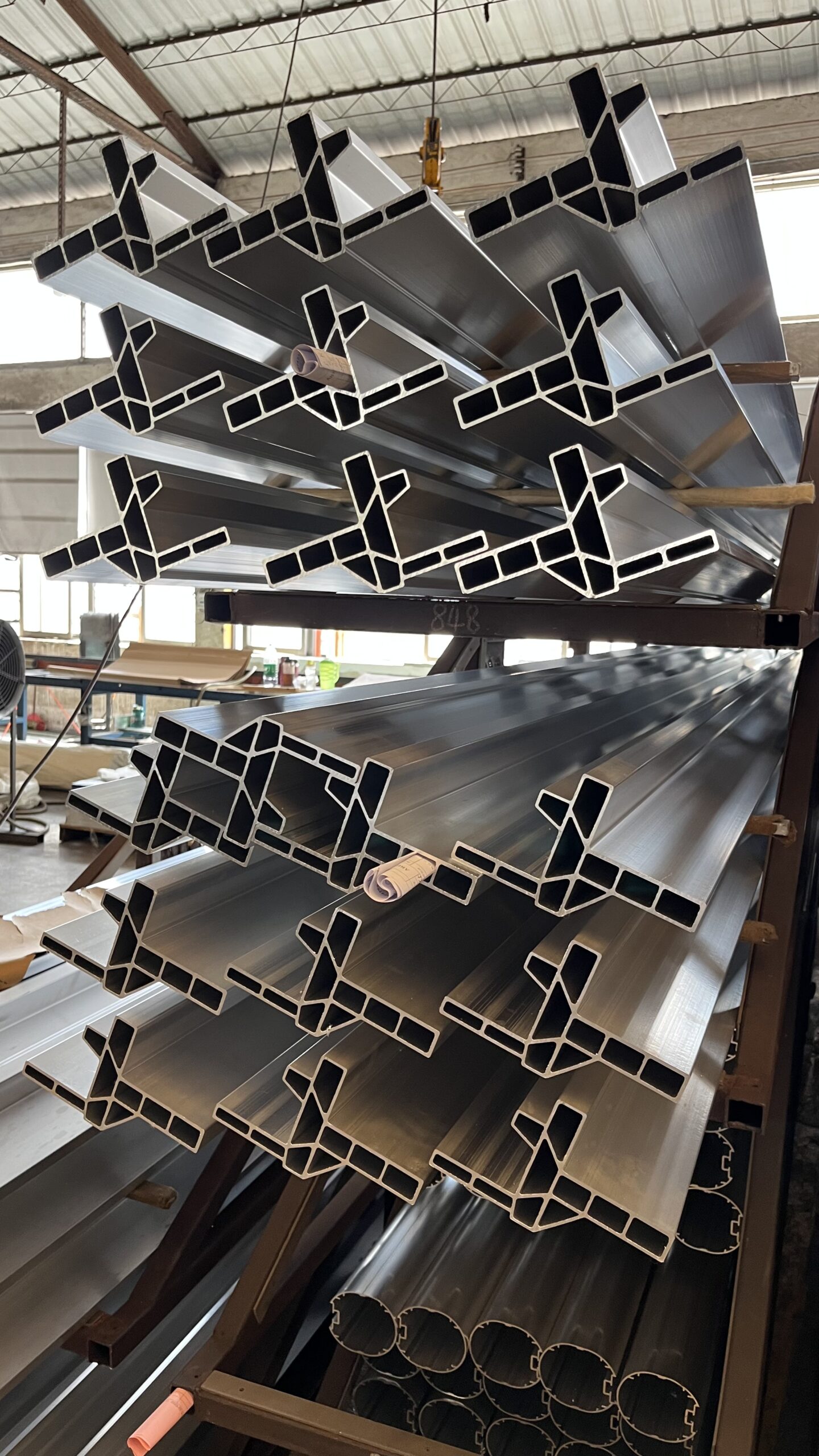

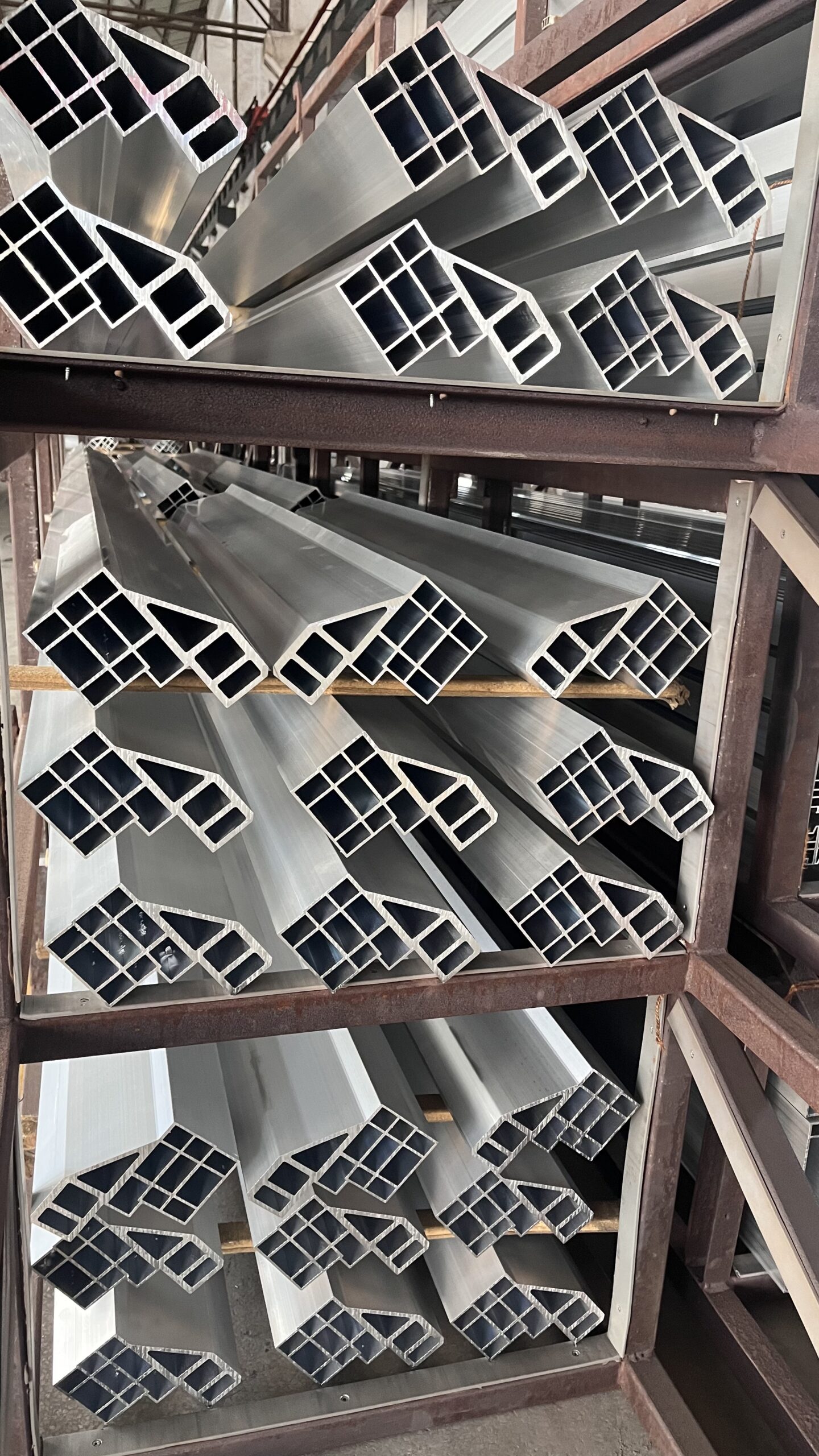

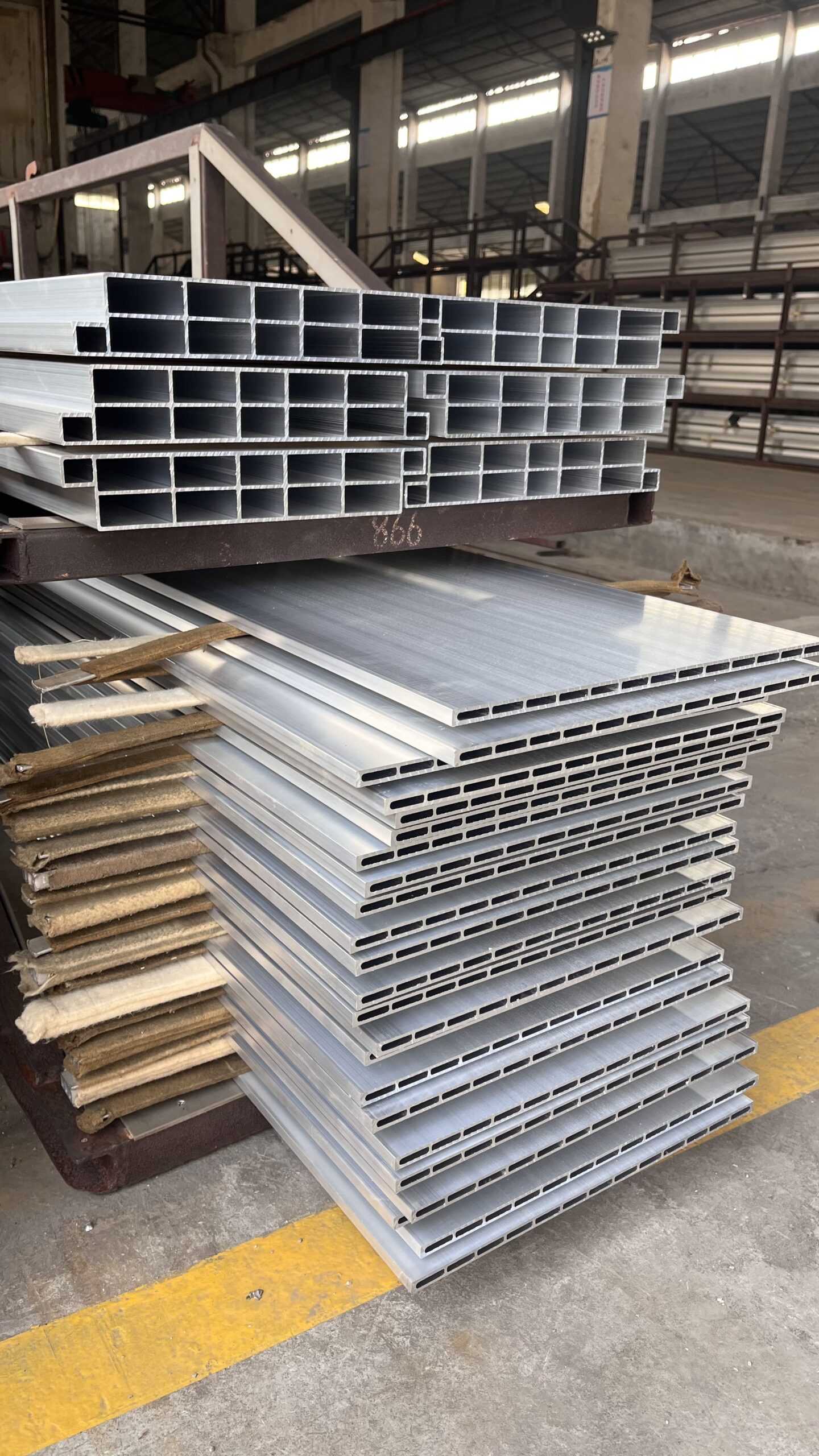

These profiles aren’t just complex – they demand precision engineering to avoid costly failures. Thin-floor sections under 2.0mm (often 6063) warp mid-span; multi-cavity beams (6005/6061) snap delicate mandrels from cross-rib stress; heavy structural beams (6082) battle distortion from uneven quenching; and hybrid thick-thin walls cool inconsistently, causing twisting and surface shadows. Add critical weld seams in thick hollow sections, and you’ve got a perfect storm for production headaches.

When designing porthole dies for these challenges, metal flow balance is non-negotiable. Increase extrusion ratios? Expand port areas to lower pressure and prevent distortion. Decrease ratios? Shrink ports to boost weld integrity. Always allocate 10-20% more flow to outer ports than center ports. Strategic weld placement in low-stress zones matters more than aesthetics. Simplify back ports by clustering them (never through the die center!), add draft angles to accelerate metal, and anchor solid sections off-center or under bridges.

Anticipating distortion is equally critical. Compensate die openings *before* scaling for shrinkage – pre-camber large hollow sections and mandrels.

Work belts aren’t universal: shorten them for thin walls, but use chokes or two-stage chambers to control thick sections since over-long belts guarantee surface defects.

The hard truth? Successfully extruding 6000-series alloys (6061/6082) into EV profiles hinges on four pillars: precision die design, premium tool steel with optimized heat treatment, consistent alloy quality, and tight process control. Compromise on dies, and you’ll pay in downtime and scrap.

For those specifying EV extrusions: what design challenges keep you up at night?

For those specifying EV extrusions: what design challenges keep you up at night?